İntrimod

The Intrimod wastewater treatment system provides many advantages compared to other treatment systems. One of them is the system’s high efficiency, which allows for less waste production and the obtaining of cleaner water.

The system also provides an advantage with low operating costs. The Intrimod wastewater treatment system requires lower energy consumption than other treatment systems and operates with less chemical use. Therefore, it reduces operating costs and offers an environmentally friendly solution.

The Intrimod system is also environmentally friendly. It is a system that is environmentally friendly due to its small footprint in nature, low energy and chemical consumption.

Since the system has a modular design, it can be customized for use in different facilities. This modular design provides an advantage for easy installation and maintenance of the system.

In conclusion, the Intrimod wastewater treatment system is a system used for the biological treatment of wastewater. This system has many advantages such as high efficiency, low operating costs, environmentally friendly design, and modular design, which offers customizable design for use in different facilities.

-

1

The High Performance

-

2

Environmentally

-

3

Simple Operation

-

4

Low Cost

-

5

Modular Design

Sistem Detayı

INTRODUCTION

At the facility entrance, special valves are used to provide standard water pressure to the facility. Pre-chlorination is applied to prevent microbiological parameters that may come from sources.

Thanks to the turbidity meters placed on the entrance line, the turbidity value is automatically measured. The system can operate up to 200 NTU raw water turbidity. When the entrance turbidity value exceeds 200 NTU, the system automatically sends the water to the drain line. Flow control is carried out at the system entrance.

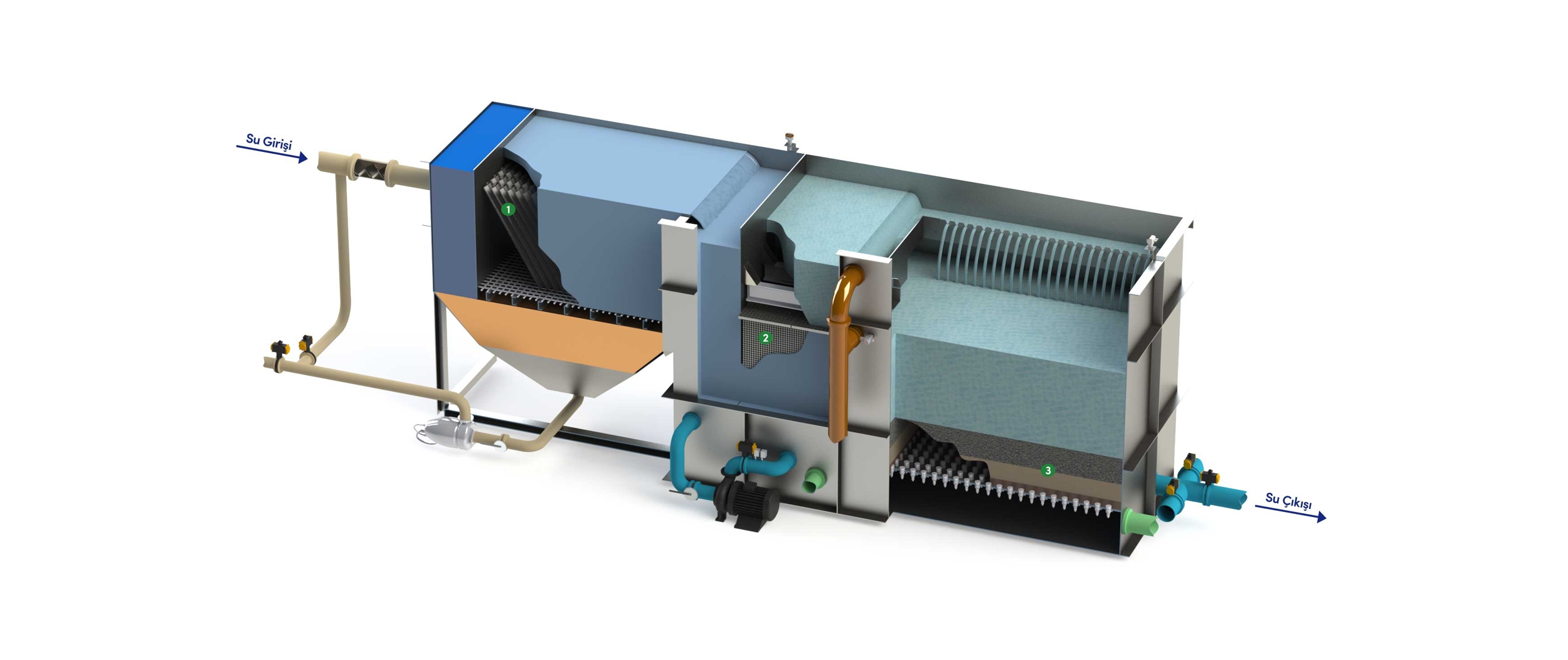

CHEMICAL LAMELLAR SETTLING UNIT

It is the unit where the coagulation, flotation, and settling sections are located at the entrance of the treatment plant. Raw waters are passed through a multilayer lamella unit that operates based on the coagulation principle to treat turbidity, sediment, color, and suspended matter in raw water. Before the chemical precipitation system, positive-charged PACS is added to the water to ensure the uniform mixture of negatively charged, suspended and colloidal particles in the water and mixed directly with a static mixer. The lamella module is located in the unit to create a surface and to ensure that the floccules formed settle quickly. Some of the settled flocks are pumped to the unit entrance to take advantage of the polymer, and the remaining excess sludge is removed from the system. The efficiency of the chemical lamellar settling unit is monitored using a turbidity meter at the system output.

ADSORPTION SETTLING SECTION

The water passing through the lamellar settling tanks is conveyed to the adsorption section by a frequency converter-controlled centrifugal pump. Cationic polyelectrolyte dosage is applied to the line between the lamellar settling tank and the adsorption section. While passing through the polymer with the help of the coagulant material, the floating flocks in the water are caught during the water passage provided from the pump pressure. The water continues to move upstream through the HDPE granule material. The water, which is reverse-filtered in the adsorption unit, passes to the sand filter section.

MIXED BED FILTER UNIT

The stainless, grooved weir structure on the sand filter section is homogeneously poured into the sand filter chamber. The stepped sand bed consists of anthracite, silica sand, and garnet. It provides high-quality filtration with this structure. Water is kept at a certain level in the unit. The water passes through the bed material at a constant speed and is directed to the outlet from the nozzle plate. After the final chlorination process on the outlet line, the treated water is sent to the treated water tank. Continuous turbidity, pH, and residual control measurements are made at the outlet of the filtration unit. The reliability of the outlet water is ensured by continuously monitoring the system.

BACKWASHING PROCESS

Backwashing is performed with air and pressurized water to dissolve the flock layer accumulated in the adsorption settling unit. The backwashing process is carried out by measuring the time and pressure inside the unit. The backwashing of the adsorption section is carried out with incoming raw water. To remove the accumulated solid materials in the mixed bed filtration unit, the backwashing process is performed with high flow rate and pressure.